B) WATER OUTLET:

This is the easy bit. If any of your coolant sensors are broken make your way to the local wrecking yard and remove a 5sfe water outlet with all the sensors attatched (make sure its off the same year 5sfe as yours just to be safe). The price you pay for the whole set of second hand sensors is half that of what you pay for a SINGLE brand new coolant temperature sensor. And if the car was able to be a write off to become a wreck, it means that the car was running and working, and therefore these second hand sensors most likely should have been working, and still should if they aren't crushed. Make sure you use every opportunity to barder at the wrecking yard. Best line of bardering to always throw out, is "Can you guarantee these work?". You would already know the answer, of course they can't. But everytime a wrecking yardie has ummed and arred, or they bring up "hey these coolant sensors are usually worth alot of money, they should be the most expensive", by saying this it has usually turned the game in my favour.

mount the 5sfe water outlet into a vice clamp. Or just use any method to hold it in place so you can remove every coolant temperature sensor on the water outlet, including the VSV (Vacuum switching valve), which is the blue capped fitting that has 2 hole outlets on it for vacuum lines). Be gentle with them, as the plastic clips to the sensors are delicate. I went through a few in the process. Remove them all as every one of these needs to be transplanted onto the 3sge water outlet (yet again, to keep the original ecu happy). Remove all the fittings from the 3sge water outlet, you dont need any of them. Fit the 5sfe water outlet fittings you just removed into the 3sge water outlet, making sure they are properly sealed either with copper washers or rub a generous amount of Selleys Black Gasket Maker silicone goop on the threads of each fitting. It doesn't matter their orientation of these fittings, fit them into any hole applicable on the 3sge water outlet. What you will notice though, is that one small 5sfe fitting is too small to be fitted into the remaining 3sge water outlet hole left over. (after you screw the other ones in) This is where that VDO adapter comes into play. Take the small sensor fitting and its hole it needs to go into to your auto parts retailer and ask for an adapter. VDO make one. If you find it, fit the VDO adapter into the hole, and that small 5sfe sensor will fit straight in. You should have a complete 3sge water outlet now with all of the 5sfe coolant sensors fitted.

--------------------------------------------------------------------------

C) DISTRIBUTOR:

The GT4 celica distributor has a housing to suit the 3sge head, and the guts to suit the plug on your original 5sfe wiring harness. You will have to do some modification though. (don't worry, no manufacturing, just parts swapping). Pull apart both your original 5sfe and gt4 distributors, (here is how: http://gtfour.supras.org.nz/sw20%20distributor.htm). You will be swapping signal rotors, so mark on the distributor shaft the signal rotor orientation so you can match another rotor back on the same way. Now remove the signal rotor from the 3sgte distributor shaft by pressing it off. I just used a bench vice and some muscle. Putting a little bit of motor oil on the shaft makes it a bliss to take off once u press it off a bit. In replacement to this 3sgte signal rotor, press on your 5sfe distributor signal rotor in the same orientation. The signal rotor is not all that firm on the shaft after all that handling and the oil on the shaft to lube it. It will require more presise tuning and more firm mounting later on. Don't let the pickups inside the gt4 concern you. You will notice in your 5sfe distributor, one of the 2 lower pickups is a 'blank' with no magnets, while the gt4 distributor uses both, and the revs pickup is in a slightly different degree orientation to the 5sfe. This is of no worry, each pickup is independant of each other, and the 5sfe wiring harness only uses 3 of the 4 prongs that come from the gt4 distributor anyways. (have a look, you will see on the 5sfe wiring harness (on the plug) that there are 4 slots, and only 3 with metal contacts inside. You can use either of the 5sfe or 3sgte distributor caps and rotors. I used a gt4 distributor cap due to the short 3sge spark plug lines. As for rotor, pick the best condition one. NOTE: if when you pulled apart your distributor you noticed the bearing wasn't all that great or there was oil all over the signal rotor and pickups, take the bearing and oil seal in the distributor to a bearing or good auto parts dealer and get replacements.

Eventually, when u start to turn the motor for the first time, put the distributor in fully retarded position. If you engine starts, do not rev it hard at the moment. If it back fires in the exhaust, its obviously too retarded, if it backfires in the intake, its too advanced. If the motor stops turning and gets 'kicked' back when you turn it over, its too retarded. You will eventually find a position for the distributor where the engine will run. Hook up a timing light and move the distributor accordingly to get the factory 10 degrees before top dead centre. At this timing, you may notice that the distributor hold down bolt may not be able to be put it to properly hold the distributor housing in place due to its orientation in the head. This is where you need to move the internal signal rotor around the shaft to have the distributor housing in a position where the hold down bolt can hold it firmly in place. The goal is to move the signal rotor inside back and forth (where needed depending on whether it needs to be retarded or advanced) by handling the spark rotor with a strong fist to turn it around the shaft so that 10 degrees before top dead centre is where the distributor hold down bolt is able to be fitted (Preferably fitted in the centre of the possible slide movement of the housing for future adjustment and play). You can always advance the ignition timing more than 10 degrees later anyways for some extra hp, as long as she doesn't ping, your set. If she pings, just pull over and retard it a little, or use higher octane petrol. If your engine runs, but in a really rough matter in that is just 'putting' along (NOT missing, but just not all alive like its just turning over), than it means its too retarded. Just advance the timing by turning the distributor clockwise.

NOTE: because the 5sfe signal rotor is able to be moved by hand on the shaft, there is a HUGE possibility upon driving and revving that the rotor will rotate around the shaft putting the set timing out of whack. After you properly set your signal rotor in a position that the engine runs at 10 degrees before top dead centre remove the distributor to fasten the signal rotor to the shaft. If u have enough confidence in an adhesive, go for it. It didn't work for me so i just did 2 spot welds to fix the rotor on the shaft and then filed the welds clean and out of the way to not interfer with the spark rotor that sits on top of it. If you do it this way, you will most likely notice the shaft won't spin around nice and easy cause of all the rubbish around it now due to the filing. Just get an air compressor and crank up the pressure and blow it all out. Get a rag and rub it between the rotor and the magnetic pickups. Get rid of most of the foreign material as possible. The celica distributors are pretty forgiving to this dirt and debree and even the heat of welding, but the cleaner the distributor the better, you want it to spin as freely as possible. Even if you have to press the shaft out a bit again to get a rag under and between the signal rotor and the base of the pickup assembly.

--------------------------------------------------------------------------

D) MOUNTING THE HEAD:

If you have an early 3sge head (mine was 1985, one of the very first), if you compare it to your early 90's 5sfe block (mine was 1990), you will notice the oil passages at either corner, and all the coolant passages match. Make sure you clean the surface of the block and remove all the old gasket and grime. A wire brush on a drill works well. It will not damage the block as it is cast iron. With the head already assembled, Cams on and torqued up appropriately (make sure u follow the torquing sequence described in your repair manual) Put the 3sge head gasket on the block. Although the 3sge head gasket is made for an engine with a slightly smaller bore, the piston will not go any further up than the top of the block and wont' cause a problem to it. The bore size difference is very small anyways, and the head gasket should be lined with metal around each cylinder for any extra strength for the very small, insignificant amount of head gasket that is exposed. The boys at the workshop and I were insistant on using a 3sge head gasket rather than a 5sfe as the 3sge head gasket lets the block coolant passages flow better. compare the old 5sfe head gasket to the 3sge and you will see how much more open the openings for the coolant passages are on the 3sge. This is a peformance head and by being so, you would assume it would require more cooling for the higher temperatures its exposed to and therefore you wouldn't want to do anything to inhibit any possible extra water flow. Hence use the 3sge head gasket. These heads are soft and can warp, bend and distort. Heat exposure can cause damages like this.

Following your service manual, bolt down the head and torque up the head bolts appropriately using your torque wrench in the proper sequence. slide on your tvis butterlies on the intake side, making sure you have already cleaned the mating surfaces and put in a fresh gasket from the VRS set. Fit the intake manifold, again with the gasket. Heres the painful part, fit the nuts onto the intake manifold studs to fasten the intake manifold and tvis butterflies in place. you will be skinning your knuckles and accomplishing the near impossible to fit the nuts and torque them up. it is applicable, but you might have to feel around blindly, or access them via under the vehicle. It was considered before putting the head down onto the block to bolt up the manifold first for ease, but the manifold and head together proved to be an obstruction to bolting the head down.

The 3sge has an oil sender mounted on the side of the head. The 5sfe wiring loom will accomodate for this, but its useless as it doesn't send the right signals. Keep it there if you want for the time being so that oil doesn't spill out. However your car will keep showing an oil warning light cause the oil sender does not send off the right signals. Go to the wreckers or remove from your original head the big round 'oil switch' (as the toyota lads call it, cause its not for a guage and therefore not an oil sender). The diameter of the oil switch might be too big or small to bolt straight into the head where the 3sge oil sender goes. If not the right size, take both your oil sender and oil switch to your auto parts store and buy some form of thread adapter.

Following the service manual, fit your timing belt and tensioner, making sure its in proper timing. If you have a 3sge oil pump pulley, you will notice the number of teeth is different. the 5sfe one has less, meaning it will turn more per number of teeth than the 3sge. This is good! this is an increase in oil pressure (without blowing seals thankfully). You may also notice that ur timing of the cams might not mesh up right with the crank and the timing belt. It may result in either being half a tooth retarded or half a tooth advanced. Go half a tooth advanced, otherwise she will be very sluggish. Your 3sge timing belt covers should now be in place, they should bolt straight up. Your engine mount on the timing belt side should be back on now as well as the harmonic balancer etc. All is left is the vacuum lines, coolant lines, distributor, exhaust manifold, coolant outlet, alternator and powersteering etc.

--------------------------------------------------------------------------

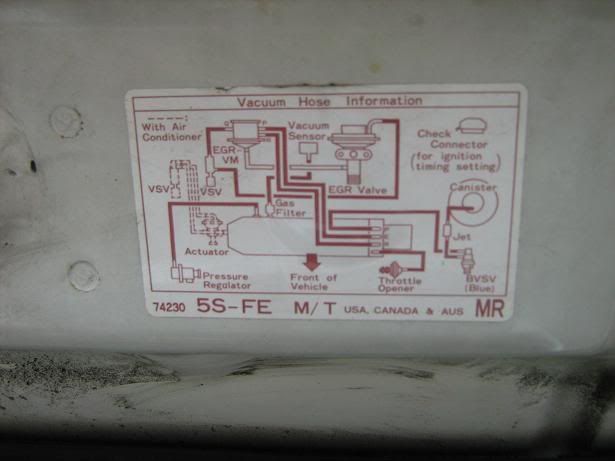

E) VACUUM AND RADIATOR HOSE PLUMBING:

Have a print out from google images or your celica workshop manual of the vacuum and cooling system diagrams. All vacuum fittings for the 5sfe NEED to be replicated as much as possible, EXCEPT the emissions components. The EGR valve, the fitting it has for the exhaust gas to recirculate into the manifold can just be blocked off with silicone. (This was done on mine as i did not have the exhaust recirculation line fitting on my exhaust manifold. This is only present on early 3sge heads, the later 3sge heads of the st162's and onwards have an exhaust recirculation fitting on the head itself.) its up to you, but its not needed. I don't have smoke pouring out of my exhaust nor foul smells from blocking off the emissions gear. The throttle body will have 3 small vacuum lines on top. 2 in the manifold direction, and one towards the air cleaner direction. Add a bit of hose to the one in the air cleaner direction and block off with a bolt. As long as your manifold pressure regulator (including its VSV) is all vacuum plumbed right, along with your brake booster and you MAP sensor, and the your set. You might as well use up the left over vacuum fittings on the manifold by plugging up the EGR valve and vacuum modulator. Any excessive vacuum lines or fittings left over should be examined as to where they belong. If they are no longer needed, they can be blocked off. I had 1 vacuum fitting in the manifold left over, and i just blocked it off. I also had to vacuum lines coming from under the car, from memory they may have been more emissions stuff, but they were then blocked off too. You may have to buy some more vacuum hose to plumb a line from the manifold to the MAP sensor, i just used some left over that i had.

As long as your MAP sensor, Manifold pressure regulator, BIG ISC vacuum fitting and brake booster is plumbed up, the car should be set. But if there are excess lines and fittings left, make sure they are blocked to prevent any vacuum leaks into the manifold. Regardless of the ones just mentioned, try your best to fit at much of the original 5sfe vacuum stuff as possible.

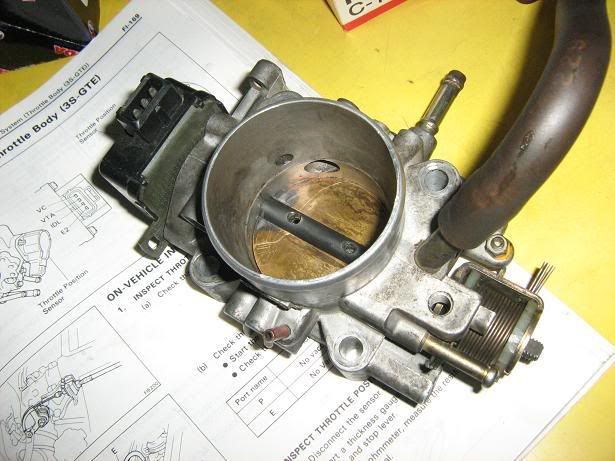

There is enough fittings on the 3sge water outlet to satisfy the original cooling system of the 5sfe (including heater). Connect up all the heater hoses, including heater return hoses. Just go along on your cooling system diagrams checking out each one. Make sure that the 3sge throttle body has the appropriate water lines going into the base of it (for the thermostat based ISC for your cold starts). There should be 3, and one massive vacuum fitting that goes into the 3sge manifold. There will also be a small vacuum line, just block off with silicone. The 3 water hose fittings that are appropriate to the 3sge throttle body ISC have coolant lines ready to be used left over from the original 5sfe setup, and are therefore sitting around in your engine bay and have to be connected up. Just use your 3sge cooling diagrams to work out where you see fit as to where they go. These 3 water lines need to be connected to the ISC to complete the coolant flow circuit.

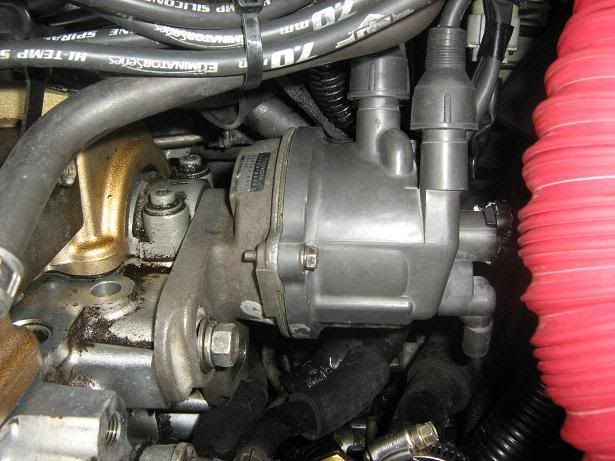

The ISC: (Notice the 3 small water hoses & the little vacuum line. You Can not see the large vacuum line leading into the manifold as it is on the other side)

Check all your hoses and plumbing while you are doing this procedure for cracks and frays. Vacuum leaks into the manifold are a pain in the backside. Use silicone gasket maker or hose clamps anywhere your gut tells you to help seal any piping for the cooling or vacuum lines.

AND REMEMBER! Use type A green coolant when you refill the radiator, which is not just anti-corrosive, but is also anti-boil and anti-freeze.

.

.  haha. (alot of experimenting went on for best possible, least bodgey solutions. This included alot of trials and mix and matching, modifying etc).

haha. (alot of experimenting went on for best possible, least bodgey solutions. This included alot of trials and mix and matching, modifying etc).

Reply With Quote

Reply With Quote

Bookmarks